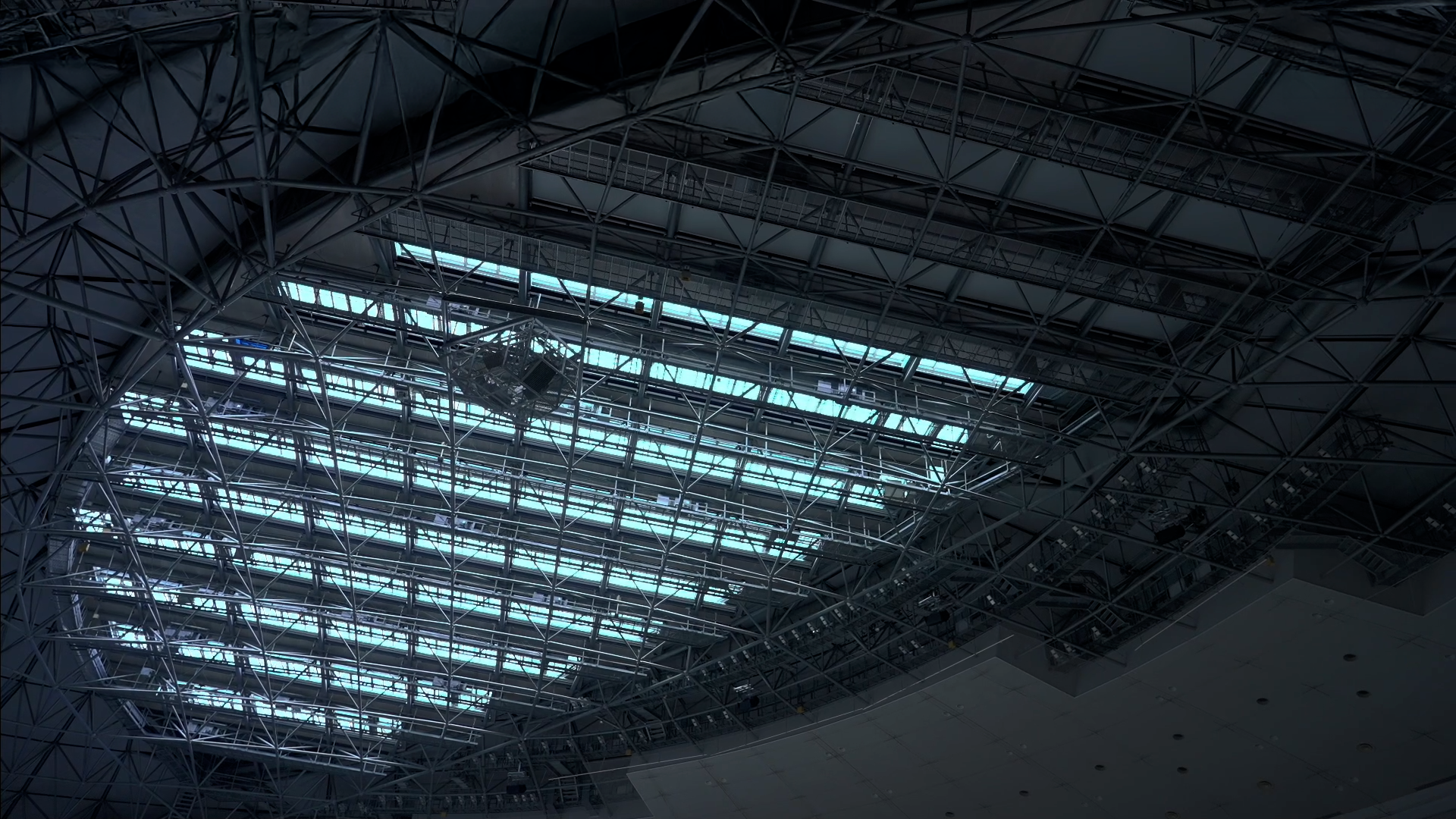

Aqua Dome Kumamoto is a comprehensive indoor sports facility located in Minami Ward, Kumamoto City.

Equipped with a 50m pool, a winter skating rink, and a training gym, it is suitable for a wide range of events, from general use to international competitions.

It has also been selected as the venue for the 2019 World Women’s Handball Championship and the 2023 World Masters Aquatics Championships Water Polo competition.

Introduction video

| Developer | Kumamoto City |

| design | Yamashita Sekkei INC. |

| construction | Obayashi Corporation, NISSAN RINKAI CONSTRUCTION CO.,LTD Tatara, Yukiyasu Construction (JV: Joint Venture) |

| structure | Reinforced concrete, steel-reinforced concrete |

| scale | Total floor area: 24,670 ㎡ Building height: Approximately 20 m Number of floors: 3 above ground, 1 below ground |

Roller blinds that allow you to freely adjust

the brightness of the room depending on the weather and the type of sport.

65 FTS motorized roller blinds were installed on the ceiling windows.

The ability to open and close the roller blinds at will makes it possible to adjust the amount of light and heat depending on the weather, the intensity of the sunlight, and the type of competition, optimizing the overall environment of the space. Not only do they soften the strong sunlight to create a comfortable environment for athletes and spectators, but they can also completely block out the sunlight, making it possible to freely create darkness. This eliminates the disadvantage of external light in indoor competitions and creates a space that can be flexibly used for multiple purposes, such as events and concerts.

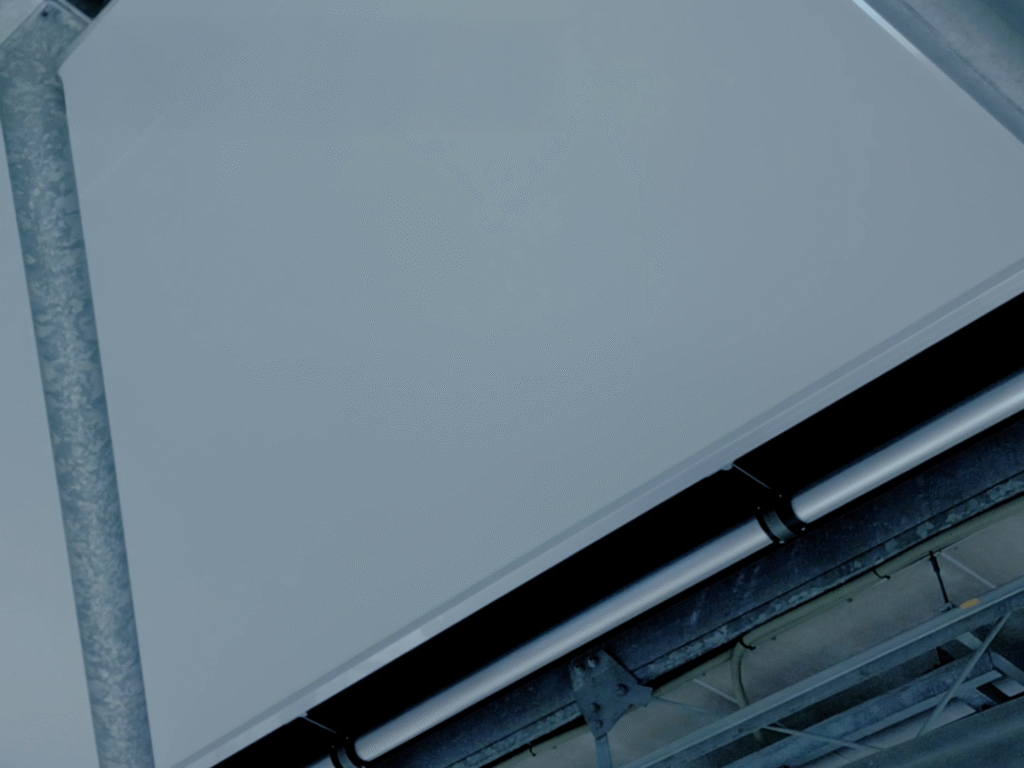

FTS enables flexible installation in three-dimensional structures.

This project required the installation of screens at different angles on a dome-shaped ceiling, so we adopted the FTS motorized roller blinds with skylight specifications. FTS stands for “Fabric Tension System,” a product that applies tension to the fabric and pulls it from both sides. This project was extremely challenging, as it required three-dimensional angles, but by adopting FTS, we were able to install it in the best possible shape to suit the building.

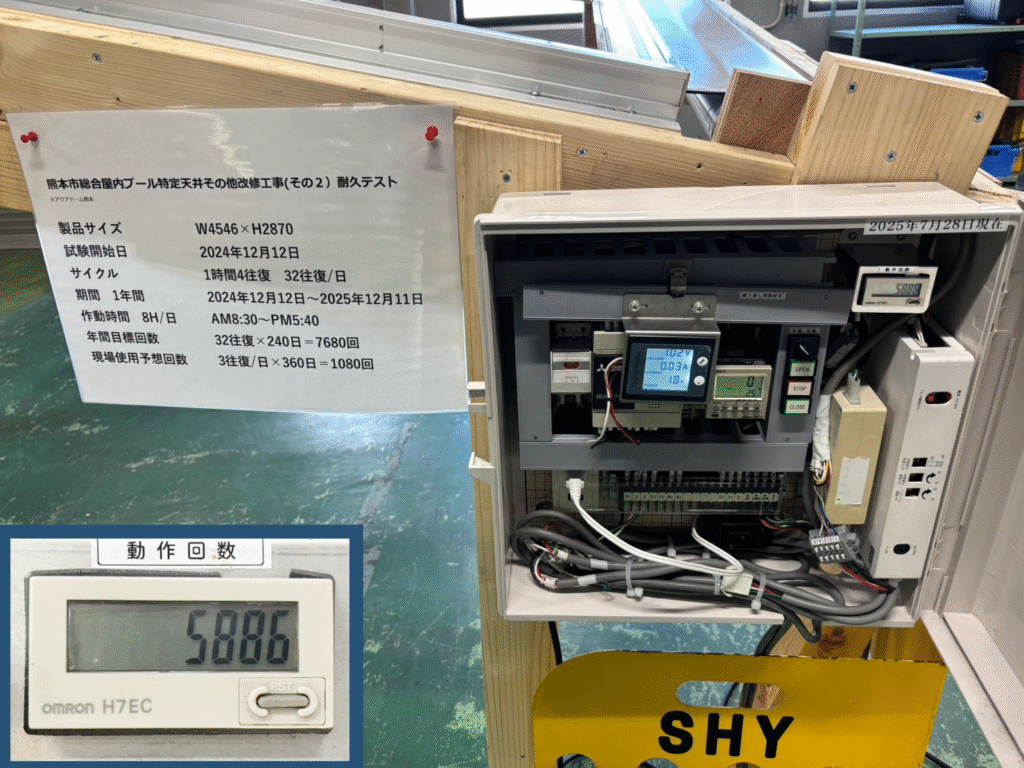

In order to recreate the actual situation on-site in detail, we created a wooden frame with the actual angles and situations, and made repeated adjustments to achieve this.

At the same time, long-term testing is being conducted to confirm the durability of the product.

The product dimensions are W4546 x H2870. Assuming operation for one year, eight hours a day (8:30 AM to 5:40 PM), the cycle is four round trips per hour, for a total of 32 round trips per day.

Actual on-site use is expected to be around three round trips per day (approximately 1,080 times per year), but in the tests, the machine is operated under conditions that far exceed those expected in the field to verify its durability.

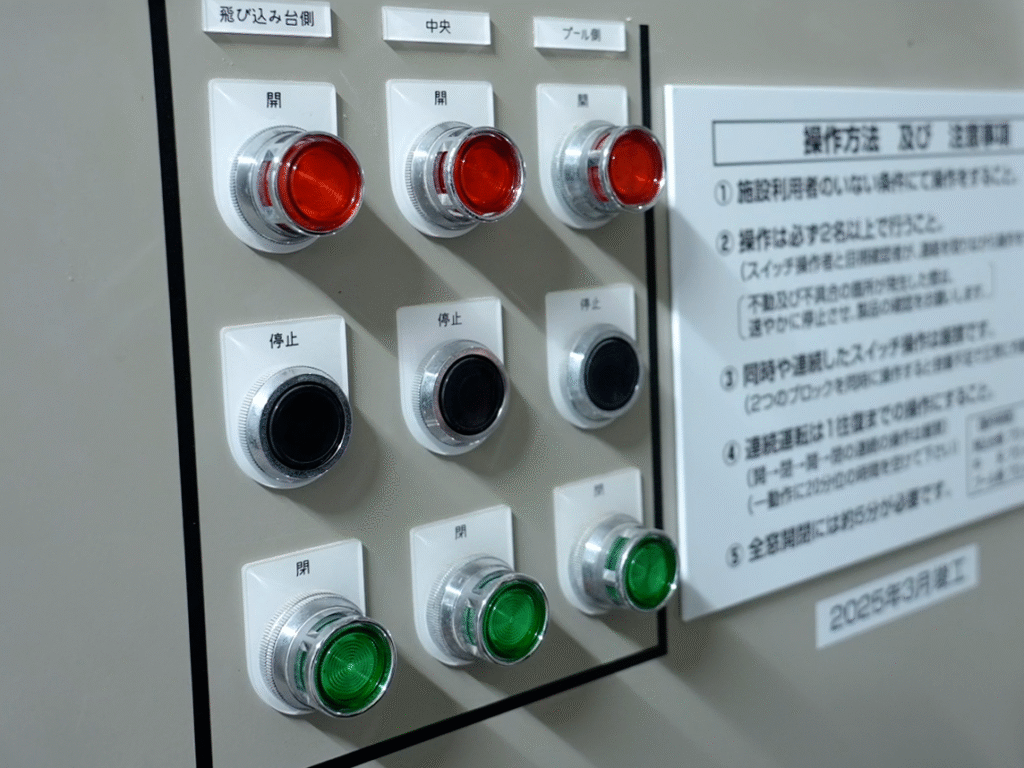

Separate design for power efficiency and ease of use

With the conventional system, all roller blinds were operated simultaneously with the push of a button, which had the drawback of placing a large instantaneous power load on the system and not allowing partial operation.

For this renovation, we proposed a separate design that allows for individual control for each area. By gently opening and closing only the necessary areas, we were able to avoid concentrated power usage and achieve efficient operation.

In addition, it is now possible to make fine adjustments according to the sunlight and the situation, greatly improving usability.

Product Information

| Product | FTS motorized Roll Screen Top Light Zipper Type |

| Material | Plain weave medium blackout fabric gray |

| Size | W4.4m×H2.9m, 65 units in total |